Cetearyl glucoside e Cetearyl alcohol (GM68, APG1618) sono un miscela contenente circa il 25% di alcoli glicosidici alkilici, ottenuta tramite disidratazione di alcoli grassi di origine vegetale e glucosio di origine vegetale.

Il GM68 è un emulsionante non ionico O/W (olio-in-acqua) dotato di effetto autoemulsionante e autoingrossante. I suoi gruppi lipofili alchilici e gruppi idrofili glucidici derivano entrambi da fonti vegetali, senza contenere solventi né sottoprodotti irritanti.

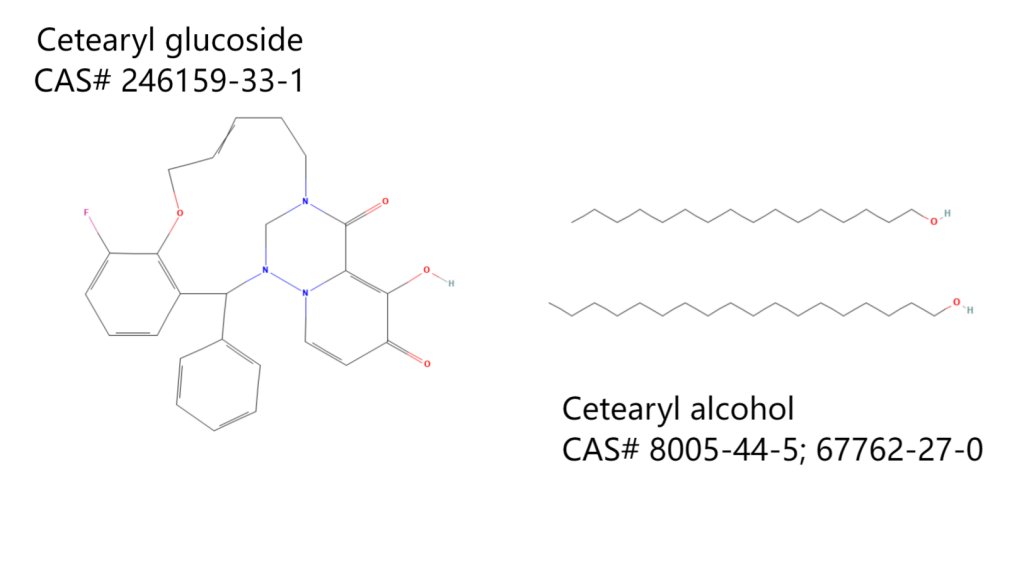

Composition/Information on Ingredients

| Chemical name | CAS Number | Component content |

| Cetearyl glucoside | 246159-33-1 | 20% to 30% |

| Cetearyl alcohol | 8005-44-5; 67762-27-0 | 70% to 80% |

Quello che segue è il testo originale inglese.

The following is the original English text.

Cetearyl glucoside and Cetearyl alcohol (GM68, APG1618) is a mixture of about 25% alkyl glycosides, which is formed by dehydration of fatty alcohols of plant origin and glucose of plant origin.

GM68 is an O/W nonionic emulsifier with self-emulsifying and self-thickening effect. Its lipophilic fatty groups and hydrophilic glucose groups are plant origin, without solvents and irritating by-products.

Performance characteristics

- 25% Cetearyl glucoside, especially easy to form liquid crystal structure, with self-emulsification and self-thickening function.

- Source of green plants, good skin affinity, mild and non-irritating.

- Excellent emulsifying performance, able to emulsify various fats and oils well.

- Strong acid and alkali resistance, stable structure, wide range of application.

- Non-ionic, good compatibility with other raw materials.

- Give the product silky plump excellent skin feeling.

- Provide moisturizing effect and slow release of functional ingredients for the system.

Technical data

| Appearance | White or pale yellow solid (flakes or granules) |

| Moisture content [%] | 1 max. |

| pH (5% water dispersion) | 5.5 to 7.5 |

| Hydroxyl value | 270 to 290 |

| Acid Value [mgKOH/g] | 1.0 max. |

| Melting Point [℃] | 60 to 70 |

Scope of application

Various O/W emulsification systems, especially suitable for high-grade functional emulsification products, such as moisturizing anti-aging products, sunscreen products, baby products and so on.

Usage and dosage

Usage: Add oil phase, heating to 75-85℃ melting, emulsification after high speed homogenization to obtain a fine and uniform paste.

Recommended dosage: 0.5-5%.

Note

During the cooling process after emulsification, the liquid crystal of the system is gradually formed, and strong agitation should be avoided to avoid destroying the orderly structure of the liquid crystal.

Packing and storage

25kg per bag, cardboard drum. Store in a cool and dry place.

Shelf life: 3 years.

Related products

Cosmetic Ingredients: Hydroxyethyl urea, Cetearyl glucoside, BTMS

Biocidal Active Substances: Parabens, Quats, Guanides, Bromine, etc.

Chelating Agents: GLDA, MGDA, EDDS, ASDA, PASP, IDS, Etidronic acid, etc.

Alkyl PolyGlycosides (APGs): APG0810, APG1214, APG0814;